The ITER TFC project: SIMIC's response to technological challenges

P. Barbero, M. Bolla

SIMIC

M. Spagnolo, G. Falcitelli

EnginSoft SpA

The magnet system of ITER consists of 48 superconducting coils of different sizes, shapes and performance and is subdivided into 4 sub-systems, i.e. the Toroidal Field Coil system, the Poloidal Field Coil system, a central solenoid and the correction coil system.

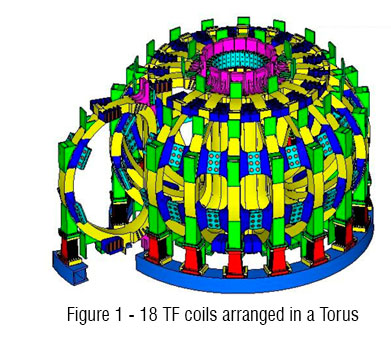

The Toroidal Field Coil system consists of 18 TF coils arranged at assembly around a torus, as shown in the following image:

The magnet system of ITER consists of 48 superconducting coils of different sizes, shapes and performance and is subdivided into 4 sub-systems, i.e. the Toroidal Field Coil system, the Poloidal Field Coil system, a central solenoid and the correction coil system.

The Toroidal Field Coil system consists of 18 TF coils arranged at assembly around a torus, as shown in the following image:

Each of the TF-Coils consists of a super conducting Winding Pack (WP) enclosed by a stainless steel casing. This casing is the main structural component of the TF-magnet system; the dimensions of one TF-Coil are ~10m high and 8m width and it has a weight of ~350 tons.

SIMIC has to manufacture 10 of the 18 TF coils and to design and to manufacture all the special tools necessary for performing the job. One of the crucial tool is so-called assembly rig, meaning the system by which the WP will be inserted in the stainless steel casing; the topic is challenging because the items bend below their own weight and there are stringent limits about the deformations the WP can undergo.

FEA calculations are therefore mandatory, not only for the simulations of the WP insertion by which SIMIC is setting up the related procedure but also for the welding simulations which aim is to predict the behavior of the system when, at the insertion completion, the closure plates are welded to the cases.